Applications and benefits of Gear Tester

Spur Gear Inspection

Internal Gears

EV Gearbox

Benefits

Manual v/s GearMate

Spur Gear Inspection

Spur/Helical Gear

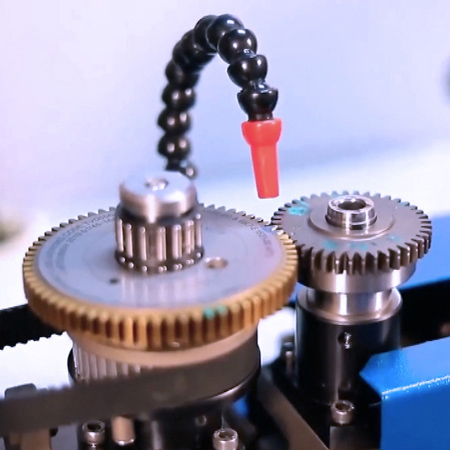

Inspecting the quality of spur or helical gears poses certain challenges. Achieving accurate and consistent measurements can be difficult due to the complex geometry and surface finish of the gears. Ensuring proper tooth profile, alignment, and contact patterns requires specialized equipment and expertise. Additionally, detecting internal defects such as cracks or inclusions can be challenging without destructive testing methods. CalibroMeasure’s GearMate helps to overcome these challenges with advanced inspection techniques with our team’s thorough understanding of gear manufacturing processes.

Internal Gears

Internal Gear

Internal gear quality inspection poses specific challenges due to the restricted accessibility and visibility of internal gear components. The inspection process requires specialized equipment and techniques to accurately assess tooth profile, alignment, and surface finish. Detecting and evaluating potential defects, such as pitting or wear, becomes more challenging due to limited external access. CalibroMeasure has proven solutions to inspect internal gears to ensure the integrity and performance of internal gears.

EV Gearbox

EV Gear

Quality inspection of electric vehicle (EV) gears presents unique challenges. EV gears often have compact designs, making it difficult to access and inspect internal components. Ensuring proper meshing, alignment, and tooth profile accuracy is crucial for efficient power transmission. Additionally, the high torque and load requirements of EVs demand robust gear quality. CalibroMeasure helps to overcome these challenges with specialized quality inspection equipment, and expertise in EV gear manufacturing processes to ensure optimal performance and reliability.

Benefits

Industry 4.0 ready features like

Gear Tester Data saved against QR code and transferred in real time to server.

Process operation

Setting gear tester process made so easy that an unskilled operator can do it.

Zero rejection

GearMate calculates and compensates the “master runout” for ensuring zero rejection skipping to customer

PDI reports

Automatic and instant PDI reports for gear inspection process.

Ensure TCE/TTE detection

Nick detection feature detects gears making noise even when TCE/TTE are within the tolerance span..

Manual v/s GearMate

Manual Gear Rolling Tester

- No assurance of ‘zero’ rejection

- No traceability or accountability

- Difficulty in locating exact tooth error

- Dependence on skilled manpower

- PDI Report generation is tedious

RollSmart Gear Rolling Tester

- Zero rejections skipping PDI

- Excellent ROI

- Assured customer delight

- Service support within 24 hours

- Eliminate line stoppages due to gear rejection

Watch video

Gear Tester - CTQ Parameters

- Span measurement (attribute/ quantified type)

- Diameter Over Ball (DOB/MOT) (attribute/quantified type)

- Center distance

- PCD runout of splines/ gear

- Internal Diameter

- Outer Diameter

- Face runout & various other runouts

- Lengths

- Groove width & groove distance

- Diameter Under Ball (DUB)

- TCE/TTE of internal gears

Shift to most advance way of gear inspection

Setting process made so easy that unskilled operator can do it

Case Study

Automation ensures zero PPM rejection in internal gear inspection

Blog

Zero Defect PPM (Parts per million) Rejection in Gear Final Inspection Process by Single Person

Blog

Electric Vehicle Gearbox and Transmission manufacturers in India are eying a rapid growth.

Learning by sharing

At CalibroMeasure, we receive many RFQs. They often come with detailed

The design and manufacturing of transmission gears is facing new performance

Auto Gear Roll Tester to inspect 5 parameters and 9 variants

Inspection of Gear by checking 16 parameters on 4 variants in